Polycarbonate Lenses have gained tremendous popularity in recent years. They are known for their lightweight nature and high impact resistance. These lenses are made from a unique thermoplastic material. This gives them durability, making them ideal for various eyewear applications.

Many people choose Polycarbonate Lenses for their safety features. Unlike standard lenses, they can withstand significant force without shattering. This is particularly important for children and athletes. However, some users might overlook the potential for scratches. It's essential to consider lens coating for enhanced protection.

The versatility of Polycarbonate Lenses is another reason for their popularity. They are suitable for prescription glasses, sunglasses, and safety goggles. They can easily adapt to different prescriptions and styles. Yet, these lenses may not offer the same optical clarity as higher-end materials. Consumers should weigh the pros and cons before making a decision.

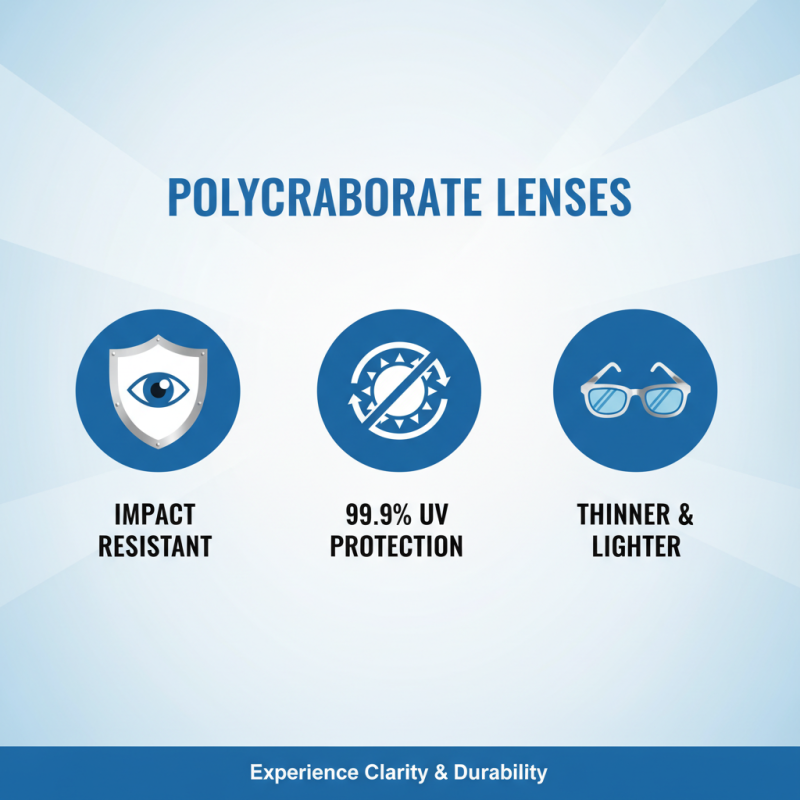

Polycarbonate lenses are a type of eyewear lens made from a lightweight and durable material. These lenses are known for their high impact resistance and optical clarity. According to recent industry reports, polycarbonate lenses block about 99.9% of harmful UV rays, making them an excellent choice for outdoor activities. Their high refractive index allows for thinner lenses, which is especially beneficial for strong prescriptions.

The popularity of polycarbonate lenses has surged over the last decade. They are often preferred by active individuals and children due to their toughness. A study by the American Academy of Ophthalmology highlighted that polycarbonate lenses are 10 times more impact-resistant than traditional plastic lenses. This factor is particularly crucial for safety eyewear and sports glasses. However, while they offer many advantages, some users note that polycarbonate can scratch more easily than glass. Regular maintenance is necessary to keep them looking good.

The ability to incorporate various coatings adds to their appeal. Anti-reflective and scratch-resistant coatings can enhance their functionality. Still, these additional treatments may wear down over time, leading to diminished performance. The lens quality can also vary widely among products on the market, so consumers are encouraged to do diligent research.

Polycarbonate lenses are known for their toughness and impact resistance. Made from thermoplastic polymers, these lenses are lighter than glass and provide high optical clarity. The manufacturing process involves molding polycarbonate resin into the desired shape. This process can include extrusion and injection molding techniques, ensuring precision and uniformity.

During production, polycarbonate is usually combined with UV blocking additives. This enhances the lens’s protective qualities against harmful UV rays. Reports indicate that about 90% of the polycarbonate lenses produced have UV protection, which is essential for eye health. The low density of polycarbonate materials contributes to their popularity in eyewear, especially for active individuals and children.

**Tips:** Look for polycarbonate lenses if you need lightweight and shatter-resistant eyewear. Ensure they are treated with anti-scratch coatings to prolong their lifespan. Remember, these lenses can be prone to scratches without proper care.

While polycarbonate lenses offer many benefits, they can sometimes distort color perception. Users might notice a slight decrease in optical clarity compared to high-end glass lenses. Regular users should be aware of this to better evaluate their needs. Understanding these aspects can lead to more informed choices in lens selection.

Polycarbonate lenses are popular due to their excellent impact resistance, lightweight nature, and UV protection. This bar chart illustrates important features and ratings, showcasing why they are favored in eyewear manufacturing.

Polycarbonate lenses are a popular choice for eyewear. They are known for their high impact resistance. This makes them suitable for sports and outdoor activities. Unlike glass lenses, polycarbonate lenses are lighter. This can enhance comfort over long periods of wear.

One key advantage of polycarbonate lenses is their UV protection. They block harmful rays effectively, safeguarding your eyes from potential damage. They also offer excellent clarity. Many users find that they enjoy the sharper vision polycarbonate lenses provide.

Tips for choosing polycarbonate lenses: Always check for anti-scratch coatings. While they are resistant, they can still get scratched. Also, consider lens thickness. Thinner lenses can look more stylish, but may not offer the same durability. Balance aesthetics with practicality.

Another aspect to reflect on is the price point. Polycarbonate lenses can be more costly than standard plastic lenses. However, the benefits may outweigh the initial investment. Consider your lifestyle and how much you value lens strength.

Polycarbonate lenses have gained popularity due to their unique properties and versatile applications. In eyewear, these lenses are lighter and more impact-resistant than traditional options. Many sports enthusiasts choose them for safety. Research shows that they can reduce the risk of injury during activities like cycling or skiing. This durability attracts not only athletes but also kids and those who lead active lives.

In manufacturing, polycarbonate lenses are widely used in safety glasses. They can withstand heavy impacts and are often used in industrial settings. According to a recent report, over 50% of safety eyewear sold includes polycarbonate materials. This ensures optimal protection in hazardous environments. In addition, polycarbonate lenses are prevalent in the production of protective visors and face shields, especially in medical applications.

Despite their strengths, polycarbonate lenses can scratch more easily than glass options. Regular maintenance is vital to prolong their life span. Users need to be aware that while they offer superior safety, scratches can obscure vision. Considering these factors can guide the selection of polycarbonate lenses for various needs.

Polycarbonate lenses have surged in popularity among eyewear users. One major factor is their impact resistance. According to a report by the Optical Laboratory Association, polycarbonate lenses are 10 times more impact-resistant than traditional plastic lenses. This makes them ideal for active lifestyles, especially for children and sports enthusiasts.

Another reason lies in their lightweight nature. The lenses weigh significantly less than glass or conventional plastic. This comfort feature encourages wearers to choose polycarbonate, especially during long hours of use. However, this advantage also comes with trade-offs. Some users report that polycarbonate lenses scratch more easily. This raises concerns about durability, leading to the need for protective coatings.

UV protection is another selling point. These lenses block up to 100% of harmful UV rays, according to the American Academy of Ophthalmology. This attribute is crucial, considering the long-term effects of UV exposure. However, not all polycarbonate lenses may offer the same quality of UV protection, sparking discussions in the industry about standardization and transparency in labeling. These factors keep the conversation around polycarbonate lenses dynamic and evolving.